Prototyping & Engineering

We turn approved concepts into precise, testable fixtures before full manufacturing. Prototypes and engineering plans confirm form, fit, and function early—reducing risk, protecting timelines, and controlling cost.

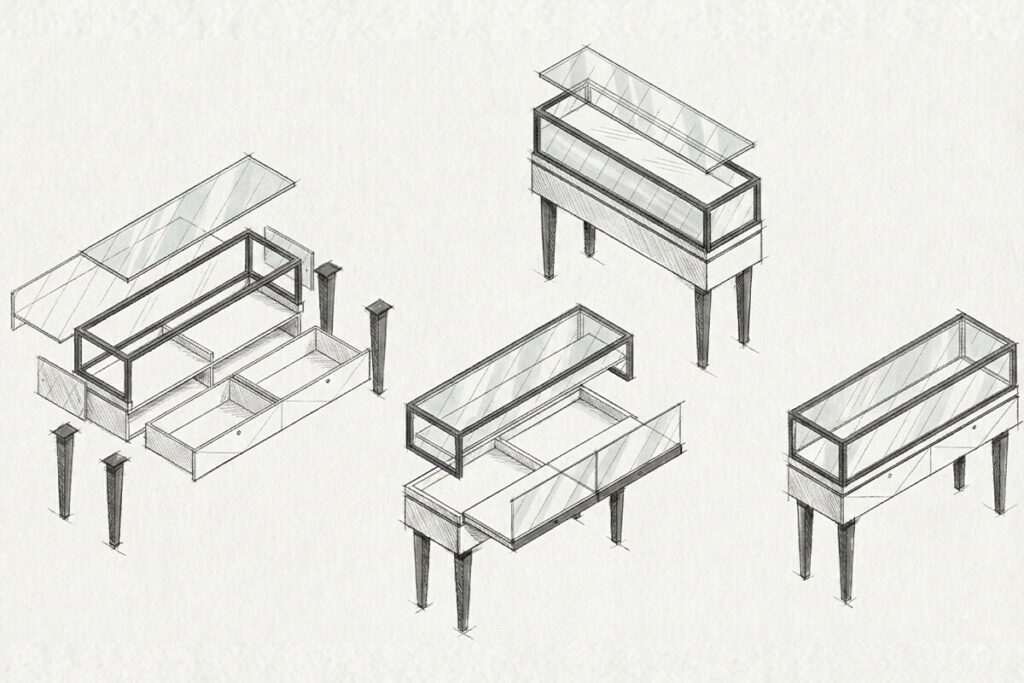

From Concept to Prototype

We convert design intent into physical prototypes that reflect real materials, dimensions, and construction methods. This allows stakeholders to review, refine, and approve with clarity.

Engineering Plans for Production

Our engineers produce detailed 3D models, drawings, and specifications that define every component. These plans become the production blueprint, eliminating ambiguity and last-minute changes.

Testing & Validation

Each prototype is tested for structure, usability, and durability. Any issues are corrected before mass production, avoiding rework, delays, and unexpected costs.

Why This Matters

Each prototype is tested for structure, usability, and durability. Any issues are corrected before mass production, avoiding rework, delays, and unexpected costs.

01

Advanced CAD & Engineering Tools

Precise models and drawings ensure accuracy and consistency.

02

In-House Prototyping

Faster development with full quality control.

03

Early Issue Resolution

Problems solved before they affect production or delivery.

04

Specification Compliance

Fixtures built to approved standards, without surprises.

Need Prototyping or Engineering Support?

Share your design and project requirements with us. We will help validate form, fit, and function through precise prototyping and engineering-so your project moves into production with confidence and fewer risks.