Material Research & Process Development

We evaluate materials and fabrication methods at the start of each project to ensure durability, visual quality, and production feasibility. Early validation reduces risk during manufacturing and helps maintain consistent results across single stores or large rollouts.

Wood, Veneer, Melamine & Laminate

We produce custom wood fixtures such as display tables, shelving, cabinetry, and feature elements. Material selections and finishes are specified to balance appearance, structural strength, and long-term durability.

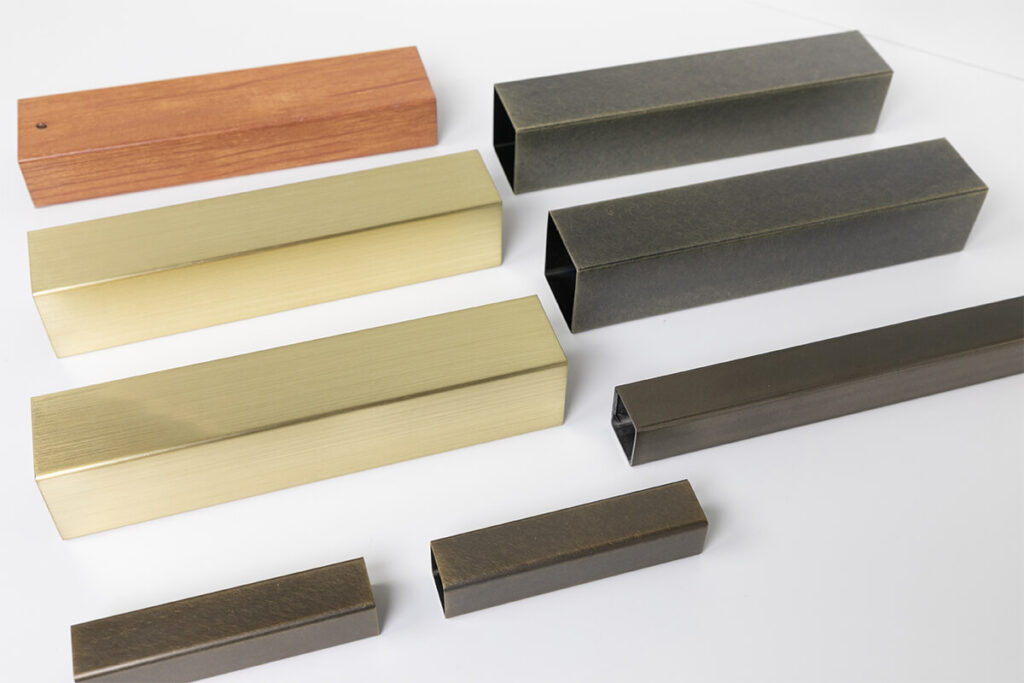

Powder Coating & Stainless Steel

We fabricate metal frames, supports, and integrated display structures using steel, aluminum, and stainless steel. Finishes are selected to meet both visual and corrosion-resistance requirements.

Paint & Stain Finishing

We apply professional paint, stain, and clear-coat finishes to wood and metal surfaces. Color standards are matched precisely, supporting large-scale rollouts with consistent results.

Solid Surfaces

We fabricate solid surface materials for countertops, cash wraps, and worktops where durability and hygiene are critical. These materials integrate cleanly with wood, metal, and stone fixtures.

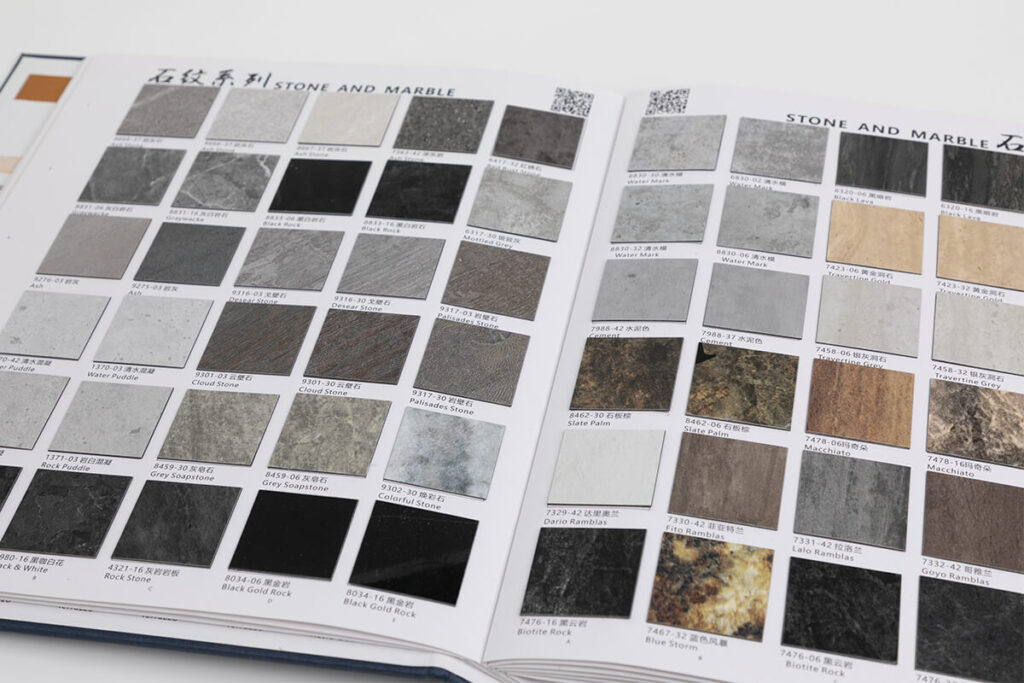

Natural Stone Surfaces

We incorporate natural stone into fixtures and feature elements where a refined, luxury finish is required. Careful fabrication ensures accuracy, safety, and long-term performance.

Glass

We integrate glass into shelving, showcases, panels, and mirrors to improve visibility while protecting merchandise. Glass elements are finished and installed to meet safety and performance standards.

Acrylic

We produce custom acrylic components for displays, signage, and illuminated elements. Fabrication methods support clear or colored designs with tight tolerances.

Need Material Research for Your Project?

Tell us about your application, performance requirements, and budget. Our team will evaluate suitable materials and processes to ensure durability, visual consistency, and production feasibility before manufacturing begins.